Hybrid PCB Mixed Material PWB Built On 10 mil RO4350B+FR4 With Blind Via

Product Description

Brief Introduction

With the development of electronic communication technology, the communication frequency is becoming higher and higher, and the high frequency signal transmission, need to use low dielectric constant (Dk), low dielectric loss (Df) but expensive special materials. These materials have cyanate and high frequency materials such as polytetrafluoroethylene / ceramic based materials (PTFE/Ceramic), hydrocarbons / ceramic based materials (Hydra Carbon/Ceramic). Usually these materials are expensive.

Reducing the cost is an important means for customers to improve the competitiveness of products. Therefore, the customers adopt the laminated structure of mixed materials in the design of PCB structure, that is, the necessary signal layer uses high-frequency materials to meet the needs of signal transmission. Other line layers are made of conventional fiberglass epoxy FR-4, which we call a hybrid board.

Available high frequency material (Core)

RO4350B RO4003C

4mil (0.1mm) 8mil (0.203mm)

6.6mil (0.168mm) 12mil (0.3mm)

10mil (0.254mm) 20mil (0.508mm)

13.3mil (0.338mm) 32mil (0.813mm)

20mil (0.508mm) 60mil (1.524mm)

30mil (0.762mm)

60mil (1.524mm)

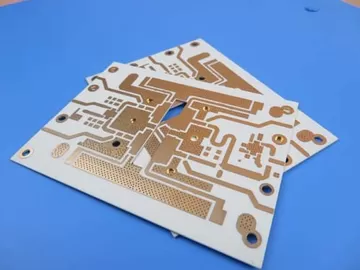

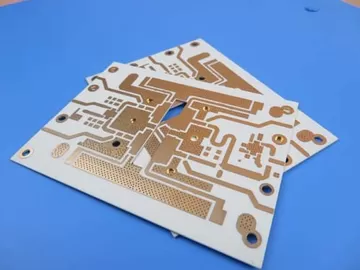

PCB Case: Hybrid PCB Mixed Material PWB Built On 10 mil RO4350B+FR4 With Blind Via

(Printed circuit boards are custom-made products, the picture and parameters shown are just for reference)

General description

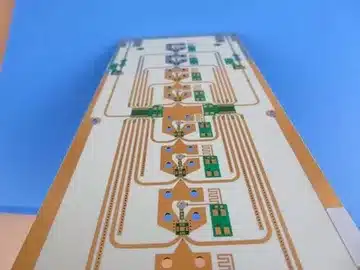

This is a type of hybrid PCB built on RO4350B and FR-4 with 6 layer stackup for the application of radar antenna. On the other hand, it’s not just 6 layer board which is directly designed from client. The designer wants a double sided RO4350B circuit board combined with a 4 layer circuit board.The 2 types PCB has it’s own drill, so the final PCB becomes a 6 layer PCB with blind via. Afer prcoess of press,it leaves 1.8 mm thick. White silkscreen over green solder mask is printed on board and immersion gold are plated on pads. The base material is used from ITEQ IT-158 and Rogers 10mil RO4350B, entire board supplying single up per panel. They’re fabricated per IPC 6012 Class 2 using supplied Gerber data. Each 25 panels are packed for shipment.

Features and benefits

SI performance improvement over the stack-ups with all FR4 board;

Cost reduction over stack-ups with all low loss material;

Excellent surface planarity for CSP mounted components to reduce failure rate during assembly and soldering;

High solderability, no stressing of circuit boards and less contamination of PCB surface;

Experienced sales persons and skilled customer services;

No minimum order quantity and low cost sample;

Focus on low to medium volume production;

Quick turnaround prototype;

ISO9001, ISO14001, TS16949, UL Certified;

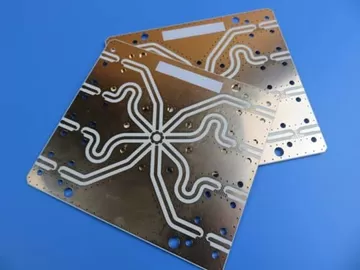

Application

Splitter, transmitter combiner , radio frequency, Tower Mounted Amplifier

| PCB SIZE | 75 x 110mm=1PCS |

| BOARD TYPE | Multilayer PCB |

| Number of Layers | 6 Layers |

| Surface Mount Components | YES |

| Through Hole Components | No |

| LAYER STACKUP | Copper ——- 35um(1 oz)+plate TOP layer |

| Dielectric RO4350B 0.254mm (10 mil) | |

| Copper ——- 35um(1oz) | |

| PP+FR4+PP 0.695mm | |

| Copper —— 35um (1oz) | |

| FR-4 0.25mm | |

| Copper —— 35um (1oz) | |

| PP 0.21mm | |

| Copper ——35um (1oz) | |

| Dielectric RO4350B 0.254mm (10 mil) | |

| Copper ——- 35um(1 oz)+plate BOT layer | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 4 mil / 5 mil |

| Minimum / Maximum Holes: | 0.3 mm / 2.0 mm |

| Number of Different Holes: | 12 |

| Number of Drill Holes: | 167 |

| Number of Milled Slots: | 0 |

| Number of Internal Cutouts: | 3 |

| Impedance Control: | no |

| Number of Gold finger: | 0 |

| BOARD MATERIAL | |

| Glass Epoxy: | RO4350B Tg280℃, er<3.48, Rogers Corp. FR-4 IT158 |

| Final foil external: | 1.5 oz |

| Final foil internal: | 1 oz |

| Final height of PCB: | 1.8 mm ±0.18mm |

| PLATING AND COATING | |

| Surface Finish | Immersion gold |

| Solder Mask Apply To: | TOP, 12micron Minimum |

| Solder Mask Color: | Green, PRS-2000GT600D, Taiyo Supplied. |

| Solder Mask Type: | LPSM |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | TOP |

| Colour of Component Legend | White, IJR-4000 MW300, Taiyo brand |

| Manufacturer Name or Logo: | Marked on the board in a conductor and leged FREE AREA |

| VIA | Plated through hole(PTH), minimum size 0.3mm. Blind via L1-L2, L3-L6 |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059″ |

| Board plating: | 0.0029″ |

| Drill tolerance: | 0.002″ |

| TEST | 100% Electrical Test prior shipment |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |