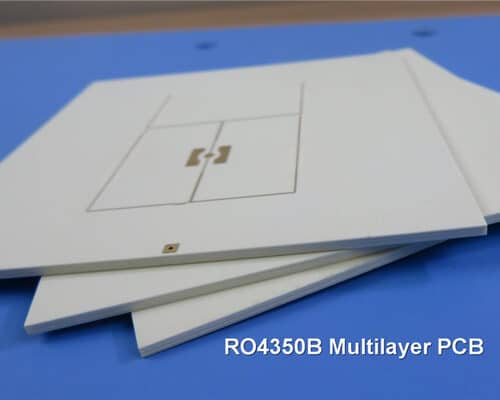

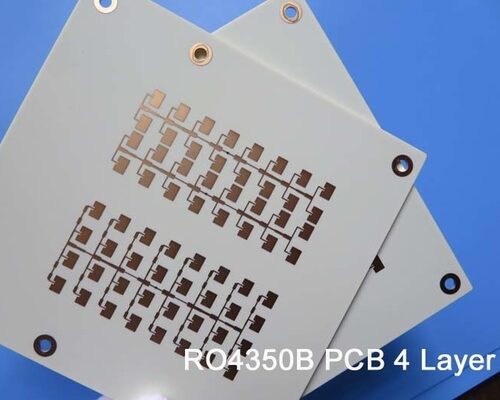

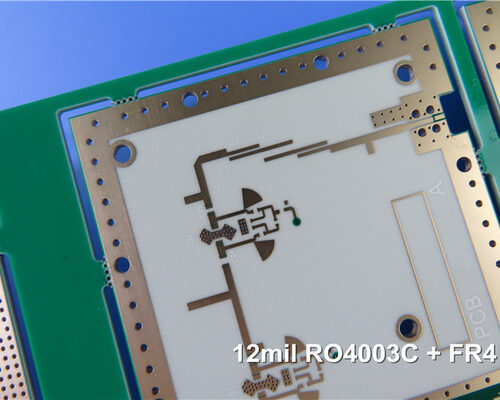

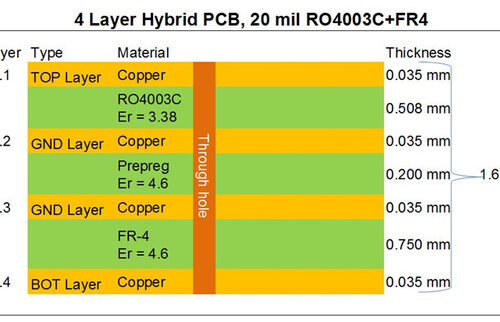

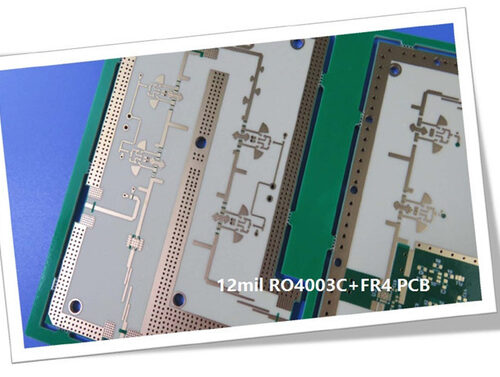

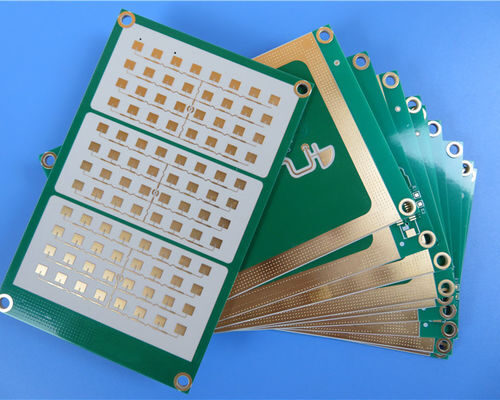

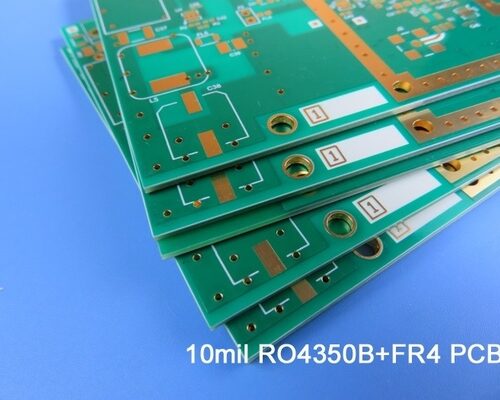

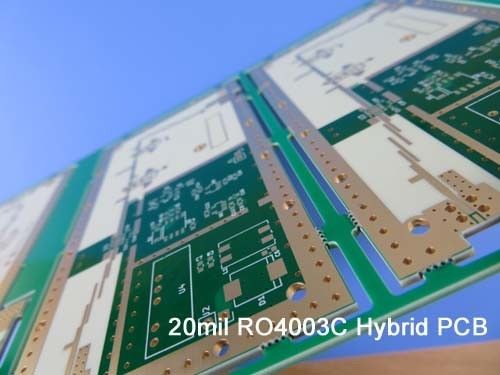

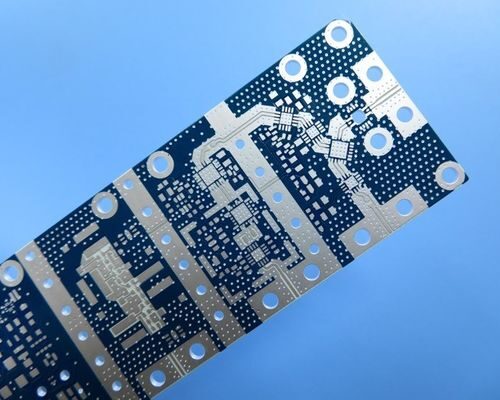

Specializing in High-End PCBs and

Unique Material Solutions

Rigid-Flex PCB

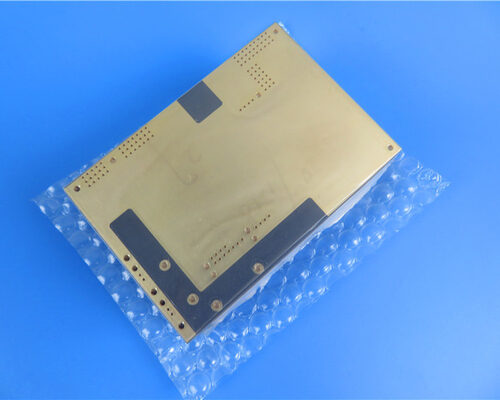

TES Copper Clad PCB

Special Material

No Minimum Order Quantity

Why Choose Us

Understanding the unique requirements of each project, we offer custom,PCB designs to perfectly align with your, specific needs.

Quality Policy

PODPCB has developed series of management procedures and approaches to assure that PCBs are in compliance with the customers' requirements, inclusive of selection of the vendors, work in progress (WIP) inspection, outgoing delivery inspection and customer service etc.

Making, audit and control of manufacturing data.

When customers' design data and specifications are provided to our market department, PODPCB has to verify all the requirements. Then, convert the design data into manufacturing data by CAM. Finally, a manufacturing instruction (MI) is generated according to the real manufacturing process and technologies for manufacturing department as the basis for actual fabrication. MI must be reviewed by independent engineers and QA engineers before issue.

Incoming Material Quality Control

All materials have to be inspected before warehousing. We established a series of strict inspection procedure and instruction to control the incoming materials. Furthermore, various precise inspecting instruments and apparatus guarantee the capability to judge the material good or not. We issue material with first in first out principle, and give out “alarm” for the material that will reach the shelf life to ensure the materials are used up before expiry.

Control of Production Process

Right manufacturing instruction (MI), comprehensive equipment management and maintenance and process control, strict WIP inspection and monitoring as well as working instruction, all those make the whole fabrication process totally controlled.

Final Control and Inspection

All PCBs have to be gone through the open and short test as well as visual inspection after passed the specified physical tests. We own various advanced test equipment including customized, probe flying test machines to guarantee that each PCB is 100% tested.

Product Delivery Audit

We set up a dedicated FQA department to inspect the PCB products according to the customer's specifications and requirements by sampling. Qualified PCBs are going to be packed. FQA also has to carry out a 100% audit of the warehouse packing and shipping products, including product number, customer number, product quantity, shipping address and so on prior to shipment.

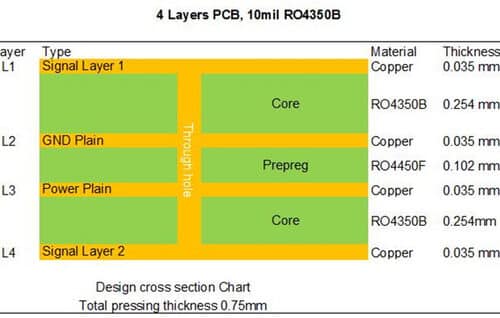

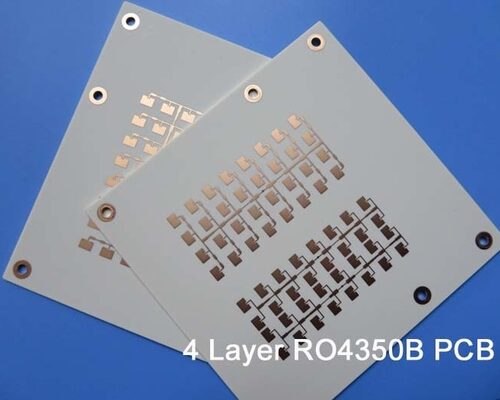

Full Manufacturing Capabilities

PODPCB provides full PCB assembly services to produce hi-tech and complicated parts using different PCB materials.

Custom PCB 1Assembly

PODPCB offers a custom PCB assembly solution to meet your different specifications. We guarantee efficient and fast service.

7/24 Online Support

PODPCB can offer 7/24 online support and our sales team can work with your local time, then give you the best support.

Our Factory & Certifications

We are an ISO 9001 & ISO 14001 certified manufacturer with over 15 years of experience in PCB production. Our facilities are equipped with state-of-the-art machinery to ensure consistent quality and fast delivery.

| Quality System and Certifications |

|---|

| IPC Specs: IPC-A-600, IPC-6012, IPC-6013, IPC-6016 (Class II and Class III) |

| Quality System Certifications: ISO 9001:2008, TS16949:2009, ISO13485:2003 |

| Environmental Certifications: ISO14001:2004, ISO/TS14067:2013 |