Microwave and RF PCB Built on Rogers 20mil 30mil 60mil AD250C Antenna Material With Dielectric Constant (DK) of 2.50

Detail Information

| Certification | UL | Model Number | BIC-207-V1.01 |

| Glass Epoxy | AD250C | Final Height Of PCB | 0.8 Mm ± 10% |

| Final Foil External | 1 Oz | Surface Finish | Immersion Silver |

| Solder Mask Color | N/A | Colour Of Component Legend | N/A |

| Number Of Layers | 2 | Test | 100% Electrical Test Prior Shipment |

| Minimum Order Quantity | 1 | Price | USD 9.99-99.99 Per Piece |

| Packaging Details | Vacuum | Delivery Time | 10 working days |

| Payment Terms | T/T | Supply Ability | 50000 pieces per month |

Product Description

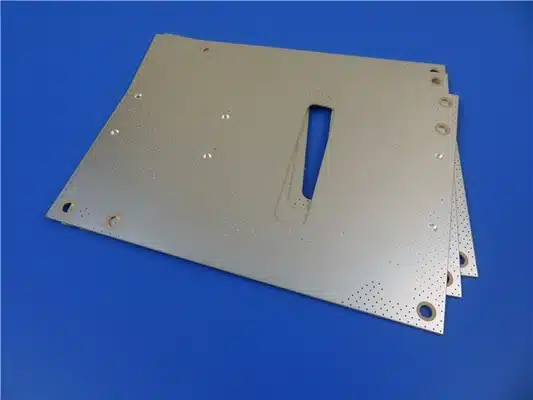

Microwave and RF PCB Built on Rogers 20mil 30mil 60mil AD250C Antenna Material With Dielectric Constant (DK) of 2.50

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

General Description

Rogers AD250C antenna PCBs are PTFE based with woven fiberglass and micro-dispersed ceramic filled composites that provide controlled dielectric constant (2.50 +/-0.04), low loss (0.0014 loss tangent at 10GHz) and low passive intermodulation (PIM) performance which is good for antenna applications. Among Rogers antenna grade materials, they are a type of cost-effective high frequency PCB for today’s telecommunication infrastructure, combining chemistry composites and design of build-up structure. AD250C PCB uses low profile copper (reverse treated ED copper foil), this helps reducing both conductive losses and antenna PIM.

Typical Properties

| Electrical Properties | AD250C | Units | Test Conditions | Test Method | |

| PIM (30mil/60mil) | -159/-163 | dBc | Reflected 43 dBm swept tones at 1900 MHz, S1/S1 | Rogers Internal 50 ohm | |

| Dielectric Constant (process) | 2.52 | – | 23°C @ 50% RH | 10 GHz | IPC TM-650 2.5.5.5 (IPC TM-650 2.5.5.3) |

| Dielectric Constant (design) | 2.50 | – | C-24/23/50 | 10 GHz | Microstrip Differential Phase Length |

| Dissipation Factor (process) | 0.0013 | – | 23°C @ 50% RH | 10 GHz | IPC TM-650 2.5.5.5 |

| Thermal Coefficient of Dielectric Constant | -117 | ppm/ºC | 0°C to 100°C | 10 GHz | IPC TM-650 2.5.5.5 |

| Volume Resistivity | 4.8 x 10^8 | Mohm-cm | C-96/35/90 | – | IPC TM-650 2.5.17.1 |

| Surface Resistivity | 4.1 x 10^7 | Mohm | C-96/35/90 | – | IPC TM-650 2.5.17.1 |

| Electrical Strength (dielectric strength) | 979 | V/mil | – | – | IPC TM-650 2.5.6.2 |

| Dielectric Breakdown | >40 | kV | D-48/50 | X/Y direction | IPC TM-650 2.5.6 |

| Thermal Properties | |||||

| Decomposition Temperature (Td) | >500 | ˚C | 2hrs @ 105˚C | 5% Weight Loss | IPC TM-650 2.3.40 |

| Coefficient of Thermal Expansion – x | 47 | ppm/˚C | – | -55˚C to 288˚C | IPC TM-650 2.4.41 |

| Coefficient of Thermal Expansion – y | 29 | ppm/˚C | – | -55˚C to 288˚C | IPC TM-650 2.4.41 |

| Coefficient of Thermal Expansion – z | 196 | ppm/˚C | – | -55˚C to 288˚C | IPC TM-650 2.4.41 |

| Thermal Conductivity | 0.33 | W/mK | – | z direction | ASTM D5470 |

| Time to Delamination | >60 | minutes | as-received | 288˚C | IPC TM-650 2.4.24.1 |

| Mechanical Properties | |||||

| Copper Peel Strength after Thermal Stress | 2.6 (14.8) | N/mm (lbs/in) | 10s @288˚C | 35 μm foil | IPC TM-650 2.4.8 |

| Flexural Strength (MD/CMD) | 8.8/6.4 (60.7/44.1) | MPa (ksi ) | 25°C ± 3°C | – | ASTM D790 |

| Tensile Strength (MD/CMD) | 6.0/5.6 (41.4/38.6) | MPa (ksi ) | 23°C/50% RH | – | ASTM D3039/D3039-14 |

| Flex Modulus (MD/CMD) | 885/778 (6,102/5,364) | MPa (ksi ) | 25°C ± 3°C | – | IPC-TM-650 Test Method 2.4.4 |

| Dimensional Stability (MD/CMD) | 0.02/0.06 | mils/inch | after etch + bake | – | IPC-TM-650 2.4.39a |

| Physical Properties | |||||

| Flammability | V-0 | – | – | – | UL-94 |

| Moisture Absorption | 0.04 | % | E1/105 +D48/50 | – | IPC TM-650 2.6.2.1 |

| Density | 2.28 | g/cm3 | C-24/23/50 | – | ASTM D792 |

| Specific Heat Capacity | 0.813 | J/g°K | 2 hours at 105°C | – | ASTM E2716 |

Typical Applications

1.Automotive Telematics Antenna Systems

2.Base Station Antenna Applications

3.Cellular Infrastructure Base Station Antenna

4.Commercial Satellite Radio Antenna

5.Digital Audio Broadcasting (DAB) Antennas

6.Radar Manifolds and Feed Networks

Our PCB Capability (AD250C)

| PCB Material: | PTFE based Woven Fiberglass/Ceramic Filled Composites |

| Designation: | AD250C |

| Dielectric constant: | 2.50 (10 GHz) |

| Dissipation factor | 0.0013 (10 GHz) |

| Layer count: | Double Sided PCB, Multilayer PCB, Hybrid PCB |

| Copper weight: | 1oz (35µm), 2oz (70µm) |

| Dielectric thickness | 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm) |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Blue, Yellow, Red etc. |

| Surface finish: | Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold plated etc.. |